|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

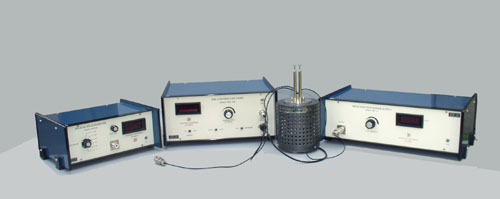

| Two Probe Setup | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Two Probe Method For Resistivity Measurement of Insulators at Different Temperatures (Ambient to 200° C) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Two Probe Method is one of the standard and most commonly used method for the measurement of resistivity of very high resistivity samples - near insulators. The resistivity measurement of such samples is beyond the range of Four Probe Method. Description of the experimental setup 1. Two Probes Arrangement 2. PID Controlled Oven This is high quality temperature controlled oven suitable for Four Probe Set-up. The oven has been designed for fast heating and cooling rates, which enhances the effectiveness of the controller. While the basic design of the controller is around the PID configuration for its obvious advantages, wastage of power is avoided by using a Pulse Width Modulated (PWM) switch. This combination has the advantages of both on-off controller and linear PID controller. The result is a good stable and accurate temperature control. Platinum RTD has been used for sensing the temperature. A wheatstone bridge and an instrumentation amplifier are used for signal conditioning. Feedback circuit ensures offset and linearity trimming to a great degree of accuracy. The set and measured temperature are displayed on 3½ digit DPM through selector switch. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > | TEKON INSTRUMENTS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T100 Network Cable Detector | 3. Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T550 Power Quality Analyzer |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T560 Power Quality Analyzer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T600 Txr Turn to Ration | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T610 Txr Analyzer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T650 ESS Diagnostic | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T700 Ind. Robot Diagnostic | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| - T800 EV-HEV Diagonstic | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||